Solar Street Light Pole Design Guidelines & Details – City and County

The Solar street light pole is usually made of steel, which is characterized by beautiful, durable, solid, easy to make various shapes, simple processing technology, and high mechanical strength.

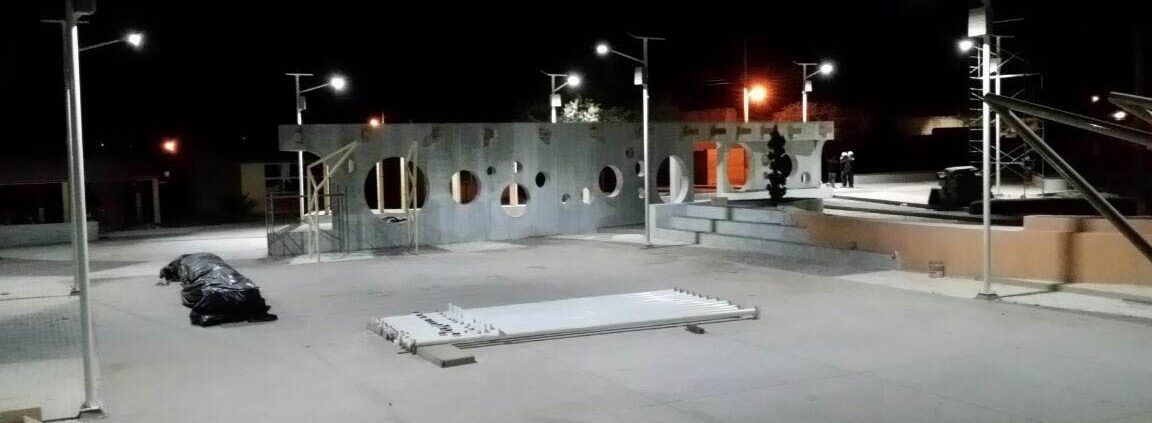

At present, more and more farms, courtyards, rural roads, and urban communities have been installed with solar street lights. Because the solar street lamps are exposed outdoors for a long time, the performance of the lamp pole itself must pass the customs, otherwise, it is likely to be rusted in the sun and rain, which will not only affect the aesthetics but also increase its risk. Below are some basic requirements for supporting the poles commonly used to support solar street lamps?

The cross-sectional shapes of commonly used tapered light poles are round and hexagonal, and some also use octagonal shapes. The taper is mostly 1:90 and 1: 100. and the wall thickness is generally 3-5mm according to the stress of the lamp pole.

The working environment of the solar street lamp is outdoor, so the requirements for supporting the lamp post are better. To prevent the lamp post from rusting and corroding and reducing the structural strength, the lamp post must be anti-corrosive.

The anti-corrosion method is mainly to take some preventive measures against the cause of rust. The anti-corrosion method should avoid or slow down the effects of humidity, oxidation, high temperature, chloride, and other factors. The common methods are as follows:

- Plastic spraying treatment: spray plastic treatment after hot-dip galvanizing. The plastic spraying powder should be selected for outdoor use, and the coating should not be peeled or cracked. Spray plastic treatment can improve the corrosion resistance of the steel pole, and greatly improve the beauty and decoration of the lamp pole. The color can also be a variety of choices.

- Hot-dip galvanizing: The process and method of immersing the pre-processed parts in the molten zinc solution to form a zinc and zinc-iron alloy coating on the surface. The thickness of the zinc layer is 65-90um. The zinc layer of the galvanized parts should be uniform, smooth, free of burrs, drippings, and excess agglomeration. The zinc layer should be firmly combined with the steel rod, and the zinc layer should not peel off or bulge.

Due to the solar street light controller and other electrical parts are installed in the lamp pole (some battery is installed inside a light pole), so you also must pay attention to a waterproof light pole and anti-theft performance, prevent the rain into the lamp post cause electrical failure, maintenance to avoid the use of conventional tools can open (e.g., hex socket bolts, pliers, etc.), prevent theft or damage.

Related article:

https://luxmanlight.com/how-to-choose-the-best-solar-street-light-factory-in-china//